AEM Hydrogen Electrode Released! JUNA TECH Upgrades Three Major Green Hydrogen Electrodes

Time:2025-01-16 00:00:00

Publisher:莒纳科技

Introduction

Recently, JUNA TECH has made another breakthrough, introducing a new generation of its three major green hydrogen electrode products. The JE Series AEM have been officially released, while the latest test data for the JA alkaline and JP PEM have been unveiled. These core products have not only achieved technical advancements but also made significant strides in commercialization. With mass production set for 2025, they will provide strong momentum for the large-scale development of the green hydrogen industry.

Research and breakthroughs in core components and materials are seen as key to overcoming homogenization and intense competition in the water electrolysis hydrogen production industry.

Against this backdrop, water electrolysis equipment and core component companies are ramping up R&D investments to accelerate breakthroughs in new catalysts, high-performance membrane materials, electrodes, and diaphragms. Among them, JUNA TECH has emerged as an industry leader, leveraging its deep technical expertise and innovation in green hydrogen electrode materials.

Recently, JUNA TECH has made another breakthrough, introducing a new generation of its three major green hydrogen electrode products. The JE Series AEM have been officially released, while the latest test data for the JA alkaline and JP PEM have been unveiled. These core products have achieved significant technical advancements and are making solid strides in commercialization. With mass production set for 2025, they will provide strong momentum for the large-scale development of the green hydrogen industry.JUNA TECH Launches the JE Series AEM

On January 15, JUNA TECH held a product launch event in Chengdu, unveiling the JE Series AEM —high-activity, cost-effective solutions designed for weak alkaline environments.

The new electrode adopts CCS method, and the cathode and cathode catalysts have high catalytic activity, with performance >3.0A/cm²@2V@60℃, and 1.0A/cm²@60℃ at a small chamber operating voltage of 1.7V. Based on the special catalyst growth process, the electrode has unique advantages such as low shedding rate and customizable production, especially the anode, which has the capacity for mass production with a maximum size of 1.2m*1.2m.

JE30000 performance curve

The highlights of the new JE series products are not only high performance, but also excellent durability and adaptability. "In actual applications, the JE30000 electrode can maintain stable performance output over a long period of operation, meeting customers' needs for efficient and stable hydrogen production.At the same time, the JE series provides a variety of substrate adaptation solutions, whether it is nickel foam of different specifications (size, PPI, surface density, etc.) or nickel felt and other substrate materials, it can achieve a good matching effect. "The person in charge of AEM electrode products of JUNA TECH pointed out.In fact, the core team of JUNA TECH has started the research and development of AEM electrode core technology and key materials since 2022. After more than two years of hard work, it launched the JE series AEM products at this time, accurately capturing the pulse of the market.AEM technology combines the advantages of alkaline and PEM , and is known as the third-generation water electrolysis hydrogen production technology. It has experienced explosive growth in the past 2024: more than ten companies have launched new products on the market, and the number of new AEM products is basically the same as that of the first-mover routes ALK and PEM, showing strong market potential.At the application level, AEM electrolyzers will gradually begin to be used on a small scale in 2024. Owners such as West Lake University and Shandong Hydrogen into Thousands of Homes Project will bid for small-scale AEM electrolyzers. China Southern Power Grid Energy Storage will use MW-class AEM electrolyzers, and high-power AEM will be commercialized.At the same time, the supply chain of AEM's core hydrogen production components is also being rapidly built in response to the matching, but it inevitably presents the characteristics of "fast but unstable" and "many but not refined". Electrolyzer customers have many pain points for AEM's electrode products, such as low cost, large size, long life, and large-scale production. Currently, there are only a few companies that can meet these demands.JUNA TECH's JE series AEM hydrogen production electrode products accurately grasp these pain points. Through electrochemical technology innovation and process optimization, they have achieved effective cost control. At the same time, they have also performed well in terms of large size and reliability. They can effectively improve the overall performance and operating efficiency of AEM electrolyzers, and promote the implementation and promotion of AEM hydrogen production technology in more application scenarios.JA Alkaline and JP PEM Innovations Revealed

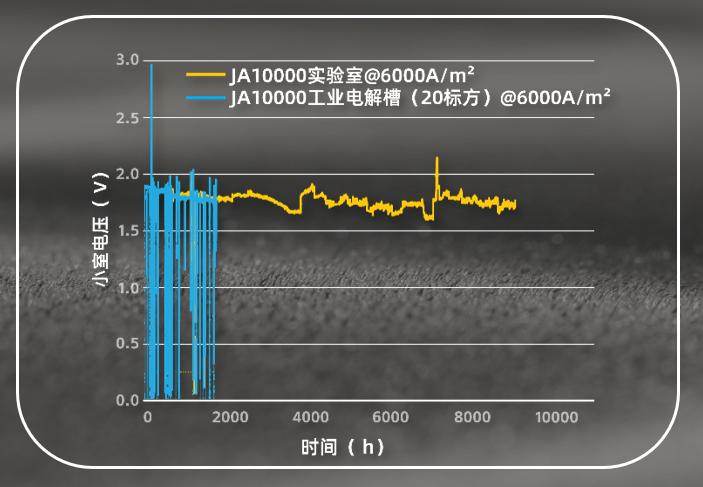

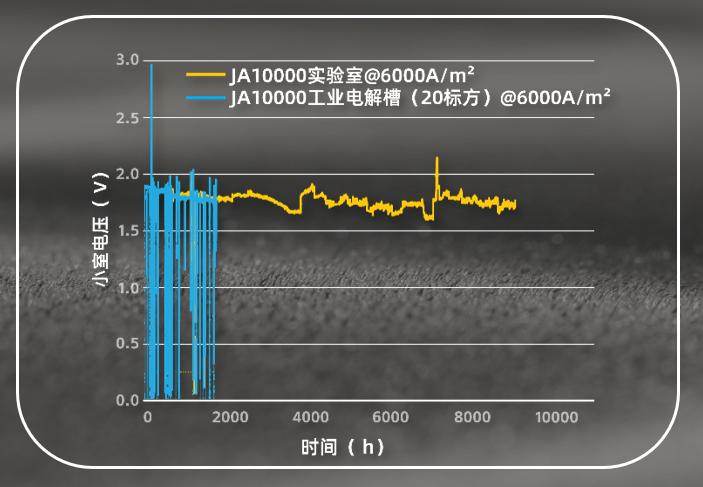

At the press conference, JUNA TECH simultaneously displayed the latest data of its two major series of hydrogen production electrode products: JA alkaline series and JP PEM series.Under the industrial-grade 20-square-cell test conditions, the JA10000 10,000-ampere-level high-performance alkaline solution electrode product achieved uninterrupted stable operation for up to 2,000 hours at 6,000A/m²@1.8V. This is a rare industrial electrolytic cell verification data that has been running stably for a long time under high-density conditions in the industry, further verifying the excellent stability of JA10000. In laboratory tests under simulated working conditions, the JA10000 electrode product has remained stable at 6,000A/m² for ~10,000 hours (continuous testing).

It is worth mentioning that the JA10000 electrode achieved an excellent performance of 1.86V 10000A/m² on a 20 square electrolytic cell with a mastoid plate structure, and conducted a long-distance stability experiment.

At the same time, multiple sets of 20-30 square electrolyzers with different plate structures/diaphragms equipped with JUNA TECH JA10000 electrodes were verified for long-term stability under different current densities (3100A/m², 6000A/m², 10000A/m²) at the Pengzhou Green Hydrogen Center, and the electrode performance was tested under start-stop (more than 1100 times) and fluctuation conditions. The results showed that JA10000 10,000 ampere-level high-performance alkaline solution electrode products have good stability under different current densities and operating conditions.The lack of industrial-grade verification data and actual working condition performance faced by the core components of electrolyzers in industrial applications has become one of the key bottlenecks hindering the technical iteration and upgrading of the entire industry. The release of the JUNA TECH JA10000 industrial electrolyzer verification data has undoubtedly set a new performance evaluation benchmark for alkaline electrode products."In 2024, the JA10000 product has successfully obtained the national first major technical equipment certification, the National New Materials Testing and Evaluation Platform (Sichuan Regional Center), and Bureau Veritas Quality Technical Services (Shanghai) third-party certification, indicating that the company has made important achievements in breaking through key technical bottlenecks and realizing the industrialization of efficient hydrogen production equipment."

JUNA TECH said: Based on the product promotion strategy of "applying one generation, developing one generation, and reserving one generation", JUNA TECH's higher density alkaline solution electrode products have completed the laboratory long-term stability verification.

In addition, JUNA TECH's mass-produced PEM JP20000 and JP30000 series products also announced the latest parameters: the ultra-low-cost JP20000 membrane electrode anode Ir loading for the hydrogen health market is as low as 0.45mg/cm², and customized services can be provided according to customer needs.

"Currently, the active catalytic area of our JP30000 PEM can reach up to 500x600mm, which can meet the requirements of different customers. We provide membrane electrode three-in-one and five-in-one products of various specifications, and provide customers with industrial verification services." JUNA TECH said.

JP30000 membrane electrode performance curve

According to JUNA TECH's testing of proton exchange membranes from different manufacturers, PEM using Juna Technology's five-in-one mass production process all showed good performance results, providing more technical support for cost-saving replacement of domestic materials.2025 will usher in batch delivery of applications!

At this point, JUNA TECH has officially become the world's second supplier that can mass-produce stable 10,000-ampere-level high-electricity-density electrodes. It is also the world's only hydrogen energy high-tech enterprise that has three major electrode technology reserves: alkaline water electrolysis technology, proton exchange membrane water electrolysis technology, and anion exchange membrane water electrolysis technology.In December 2024, JUNA TECH won the "Future Green Innovation International Intellectual Property Commercialization Award" issued by the International Intellectual Property Commercialization Committee (IIPCC). At the same time, the national standard "Performance Test and Evaluation of Electrodes for Hydrogen Production by Water Electrolysis" (GB/T 45092-2024), which it participated in drafting, was officially released and will be implemented on March 1, 2025. This is the first national standard for alkaline water electrolysis hydrogen production electrodes in China, filling the gap in the industry.As one of the main drafting units, JUNA TECH has been deeply involved in the formulation of the national standard "Performance Test and Evaluation of Electrodes for Hydrogen Production by Water Electrolysis". This standard is applicable to ALK electrodes and AEM electrodes, and clarifies the test methods for the ultrasonic peeling rate, overpotential, positive and negative polarization stability, electrolysis voltage and electrolysis voltage change rate, and fluctuating electrolysis stability of the electrode, as well as the corresponding performance evaluation requirements.With strong innovation leadership and a rigorous testing and verification system, JUNA TECH's electrode product innovations have achieved significant transformation results in the market.At present, its three major series of products, JA alkaline solution electrode, JP PEM membrane electrode and JE AEM electrode, have reached cooperation with many well-known companies due to their excellent performance and innovative features. While JA10000 and JP20000 have achieved batch orders, JP 30000 PEM five-in-one membrane electrode and JE30000AEM electrode will be delivered and applied in batches in 2025!In order to meet this important moment, JUNA TECH has made comprehensive and in-depth preparations in production planning and mass production process optimization: the GW-level digital factory of catalytic electrodes for hydrogen production by water electrolysis built in accordance with the German Industry 4.0 standard has been put into use. This factory uses the most advanced "digital twin" and "Industrial Internet of Things" technologies and equipment to realize the intelligent, automated and efficient production process, which not only ensures the high quality and high efficiency of the products, but also lays a solid foundation for JUNA TECH in future market competition."Continuous adherence to green hydrogen electrode material technology innovation is the key to Juna Technology's continuous breakthroughs." Juna Technology said. Looking forward to the future, JUNA TECH will continue to adhere to green hydrogen electrode material technology innovation, continue to deepen research and development and industrialization practices, and promote the technological upgrading and large-scale application of the hydrogen energy industry with more efficient, environmentally friendly and sustainable solutions.