Three-Pronged Approach! Overcoming Cost Challenges in PEM Electrolyzer MEAs

In recent years, China has witnessed rapid growth in electrolyzer production capacity and installed capacity, with an explosion in green hydrogen projects. The hydrogen production segment has become a focal point for both capital investment and market attention. The core components of electrolyzers include membranes, electrodes, and bipolar plates, among which electrodes serve as the reaction site for electrochemical processes and are a key determinant of hydrogen production efficiency.

JUNA TECH, as a leading green hydrogen electrode supplier, has been pushing forward with technological innovation and industrialization. Its PEM MEA has now passed sample testing by an authoritative third-party institution. By optimizing the microstructure of catalyst materials and innovating in processing techniques, JUNA TECH has significantly reduced precious metal usage in the catalyst layer and successfully tackled the challenges ofhigh costandcomplex manufacturingin PEM MEAs.

1. Lower Platinum at the Cathode, Lower Iridium at the Anode – Achieving a 30% Cost Reduction

By optimizing the nanoscale structure and composition of its catalysts, JUNA TECH enhances activity while reducing loading. The company’s cathode catalyst is based on proprietaryPt-transition metal alloy nanomaterials, while the anode catalyst adopts aself-developed core-shell structure, improving the synergistic effect of active sites, increasing the effective reaction surface area, and enhancing charge transfer to improve conductivity—significantly lowering platinum and iridium loading.

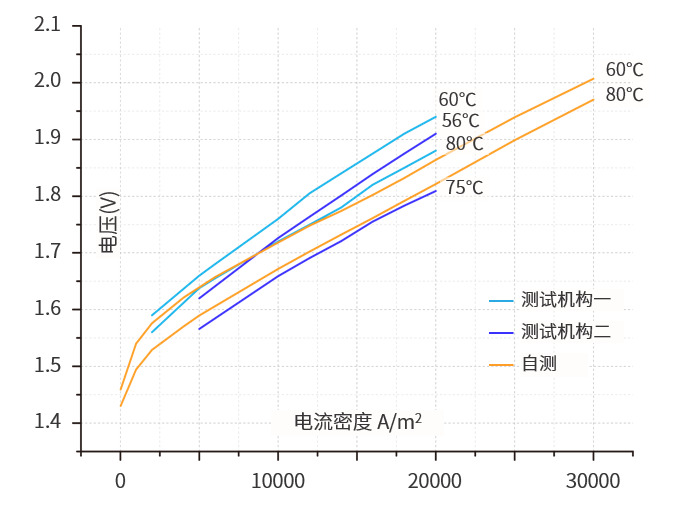

Through these microstructural optimizations, JUNA TECH’s catalysts enable its MEAs to achieve performance levels of<1.9V@2A@60°C, while simultaneously ensuring:

➤ Cathode Pt loading <0.2 mg/cm²;

➤ Anode IrO₂ loading <1 mg/cm²;

➤ Overall MEA cost reduction of approximately 30%

2. 48-Hour Slurry Stability + Continuous Coating Process for Product Consistency

The manufacturing of PEM MEAs involves multiple critical processes, including catalyst synthesis, slurry preparation, catalyst-coated membrane (CCM) fabrication, and encapsulation. JUNA TECH ensures MEA consistency through innovations incatalyst synthesis, slurry formulation, and coating transfer technologies:

➤ Precise chemical synthesistechniques, controlling parameters such as composition and temperature, ensure uniform catalyst particle size and stable performance.

➤ Advanced dispersion technology, utilizing stirring, ultrasonication, shearing, crushing, and emulsification, achieves homogeneous slurry dispersion with stability exceeding48 hours, ensuring uniformity in subsequent continuous coating.

➤ Large-width slot-die coating combined with thermal transfer technologyprevents PEM membrane swelling issues, ensuring a uniform coating and high production efficiency. This process supports high-yield coating on large-area MEAs (active area>3000 cm²).

Currently, JUNA TECH’s PEM MEA has successfully undergone sample testing by an independent third-party institution. According to electrolyzer manufacturers’ test data, the company’s MEAsmaintain performance levels equivalent to those of advanced PEM electrolysis MEAswhile significantly reducing precious metal loading, fully meeting the requirements for engineering applications.

JUNA TECH PEM MEA (CCM) test data

As green hydrogen projects rapidly expand,technological innovation is the key to avoiding homogeneous competition. JUNA TECH exemplifies China's electrolyzer technology advancements—developingmulti-pathway product innovationsand collaborating with electrolyzer manufacturers to explore new industry development strategies. Through this approach, the company isaccelerating cost reduction, improving efficiency, and driving the industrialization of electrolyzer technology.