Next-Generation Alkaline Electrodes! JA Series Officially Launched!

On the 12th of this month, JUNA TECH grandly hosted the "Alkaline Electrode Product Launch & Chengdu Factory Opening Ceremony" at its Chengdu facility. On this day, leaders at various levels, authoritative experts, and representatives from upstream and downstream enterprises gathered to witness the birth of the next-generation alkaline electrode.

During the event, JUNA TECH’s chairman summarized the company's achievements over the past year and expressed sincere gratitude to all attendees for their support and assistance.

JA Series – Next-Generation Alkaline Electrodes

Overcoming Key Bottlenecks in Alkaline Electrolysis to Achieve Significant Cost Reduction and Efficiency Gains

Following the opening remarks, JUNA TECH’s CEO officially introduced the "JA Series – Next-Generation Alkaline Electrodes", elaborating on the product’s performance and market value from multiple perspectives. This new series is designed to help electrolyzers achieve high efficiency, low energy consumption, and lightweight design.

CEO presenting the product

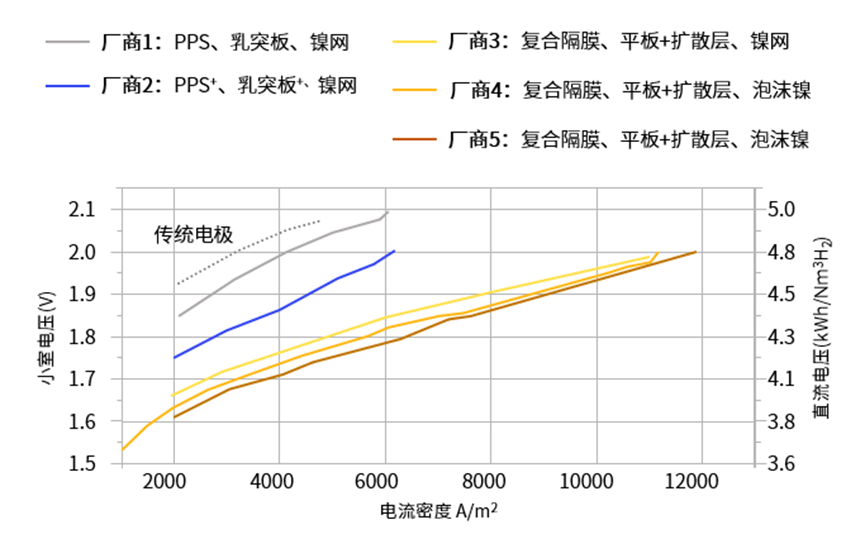

Over the past year, JUNA TECH has distributed a total of 566 test electrodes for industrial evaluation. After 1,094 hours of testing, the team identified the optimal performance configuration for JA Series electrodes—JUNA Electrode + Composite Membrane + Flat-Plate Structure + Diffusion Layer—which demonstrated exceptional results:

➤ 50% increase in current density, reaching up to 11,900 A/m².

➤ 10–20% reduction in power consumption, achieving a minimum of 3.66 kWh/Nm³·H².

➤ Customizable electrode dimensions, with sizes up to 1.9m × 1.9m.

Test data from electrolyzer manufacturers

Zhongdian Fengye, one of the signing customers and an early testing partner, stated:

"The outstanding performance of JUNA TECH’s electrodes has made us realize that electrolyzers are entering an era of ultra-high current density. By collaborating with JUNA TECH, a rising specialized supplier, we aim to leverage their high-efficiency, low-cost products to expand into broader markets."

Cost Reduction, Operational Savings, and Superior Electrolysis Efficiency

The high current density, low energy consumption, and customizable features of the JA Series electrodes provide significant advantages for customers:

➤ Lower capital investment:

With JA Series electrodes, the required number of electrolyzer cells can be reduced by at least 50% while maintaining the same hydrogen production rate, cutting electrolyzer size and material costs by half.

➤ Reduced operational costs:

By lowering the direct energy consumption per unit of hydrogen production, a 1,000 Nm³/h alkaline electrolyzer equipped with JA Series electrodes can achieve a 10% reduction in electricity consumption. Over a 10-year lifespan, this equates to approximately 40 million kWh in total energy savings.

➤ Enhanced electrolysis efficiency:

With reduced energy consumption, JA Series-powered alkaline electrolyzers now offer higher efficiency than PEM electrolysis technology, achieving a system efficiency of 78.8%, which translates to less than 50 kWh per kilogram of hydrogen produced.

Baoying Gas, another key partner and signing customer, stated:

"As a gas supplier for green hydrogen projects, we are primarily focused on reducing costs and improving efficiency in water electrolysis. JUNA TECH’s electrodes exhibit significant advantages in both efficiency and energy consumption, making them a crucial component for reducing operational costs in green hydrogen production."

Over the past year, the electrolyzer industry has experienced explosive growth. According to GGII forecasts, by 2025, China's demand for water electrolysis hydrogen production equipment will exceed 2GW, representing a sixfold increase compared to 2020.

JUNA TECH aims to accelerate this industry evolution by delivering ultra-high current density electrode products and providing customized solutions to help electrolyzer manufacturers overcome technical barriers. Through collaborative innovation, the company seeks to drive the development of new electrolyzer technologies and applications.

On the event day, JUNA TECH secured over ¥10 million in orders from key customers including Baoying Gas, Zhongdian Fengye, and Guofu Hydrogen, marking the company’s first major market validation.

As Guofu Hydrogen, one of the signing customers, stated:

"In the electrolyzer sector, we have always maintained a ‘rigorous yet open’ approach, willing to explore both alkaline and PEM electrolyzer technologies in pursuit of breakthroughs. Our collaboration with JUNA TECH has shown us the possibility of pushing alkaline electrolyzers beyond their current performance limits. We hope this partnership will not only bring mutual benefits to both companies but also open a new chapter for the entire industry."